Dual Lean Six Sigma Green and Black Belt Training

Categories

Featured, Lean Six Sigma Certification

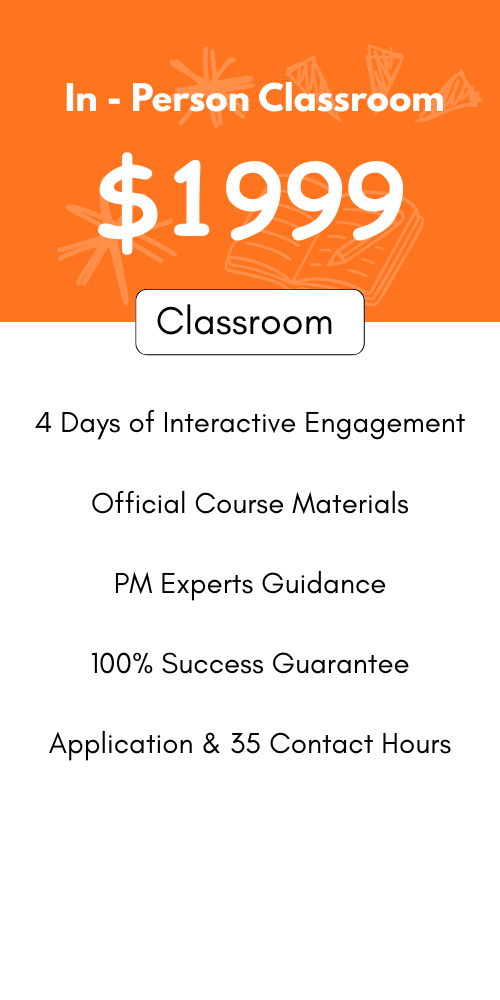

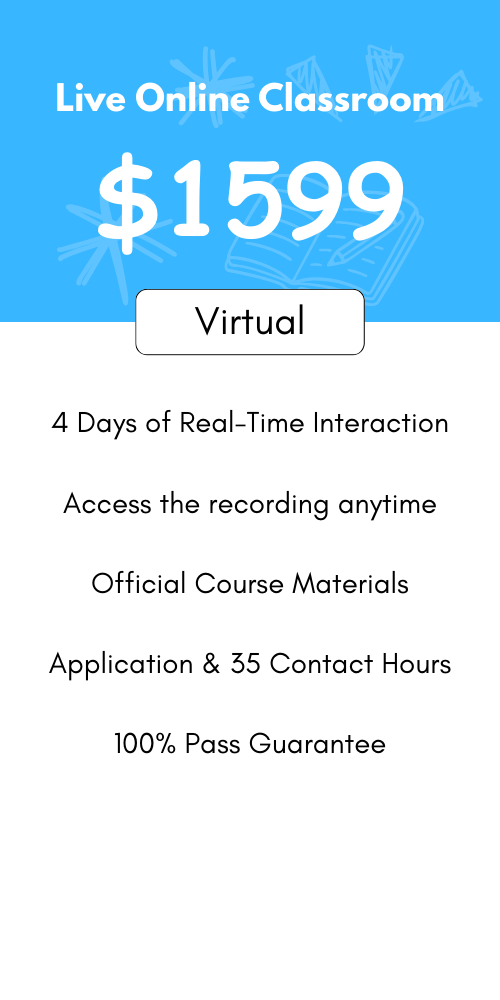

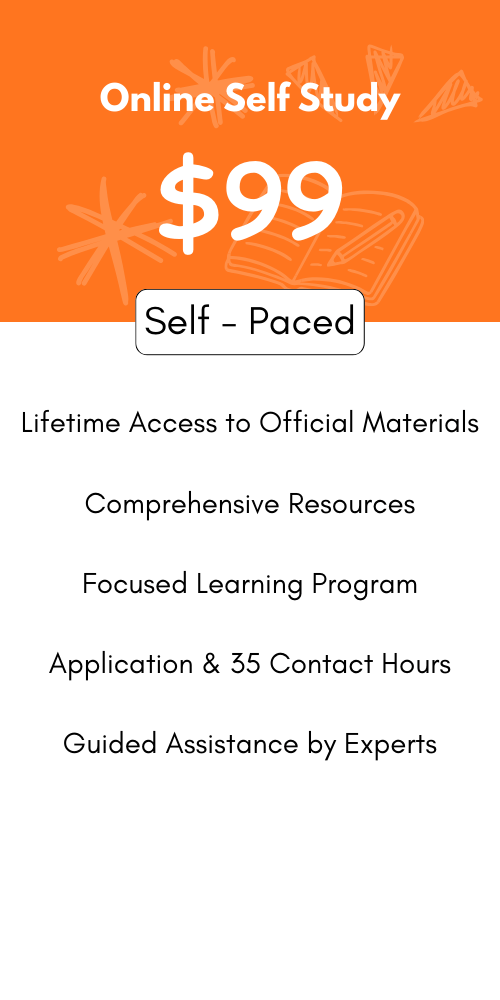

$99 – $2,099Price range: $99 through $2,099

$99

-

LevelIntermediate

-

Duration60 hours

-

Last UpdatedJanuary 15, 2026

Hi, Welcome back!

Pre-Requisites

- No prior Lean Six Sigma certification required

- Basic understanding of business or process workflows is helpful

- Stable internet connection for online sessions

- Certificate soft copy will be emailed within 48 hours of course completion

Who Should Enroll

- Project managers

- Engineers and process engineers

- Quality professionals

- Business analysts

- Operations managers

- Professionals seeking Green & Black Belt certification

Courseware Includes

- 4 days of instructor-led classroom or live online training

- Lean Six Sigma Green Belt & Black Belt certificates

- 60 contact hours (PDU) certificate

- 400 practice questions for first-attempt exam success

- Simulation tests for LSSGB & LSSBB

- Downloadable course materials designed by industry experts

- Industry-based case studies and real-life examples

- Lifetime access to downloaded course materials

- 100% money-back guarantee

Description

Certification Guide offers an optimized Dual Lean Six Sigma Green and Black Belt Training program that enables professionals to achieve two globally recognized certifications in a single, comprehensive course. This in-depth training is designed by industry experts and focuses on real-life examples, simulations, and hands-on case studies to build strong practical competence.

This program combines Lean methodologies for waste reduction with Six Sigma’s data-driven quality improvement techniques, helping participants lead process improvement initiatives and drive operational excellence across industries.

FAQs

Does the course fee include the examination fee as well ?

Exam fee included in the course fee (Third Party exam fees are not included in the fee (ASQ – $438, IASSC – $295 individually for LSSGB & LSSBB separately)

Will I get the Dual LSSGB & BB ® certificate after completing this Dual LSSGB & BB ® certification course ?

On completing the LSSGB Training course from Certification Guide, you will get a contact hours (PDU’s) certificate from Certification Guide.

Does Certification Guide offers 100% money back guarantee ?

Yes, we offer 100% money back guarantee on our Dual LSSGB & BB training. CLICK HERE to know more about the money back guarantee.

What kind of course completion certificate is provided after the training ?

On completion of 4 days of In-person/online training, you will receive a 60 contact hours certificate along with the participation certificate. Certificate soft copy will be mailed to your registered email address within 48 hours of course completion.

How long the course materials access will be provided ?

All registered participants will receive a link to download the courseware from Dropbox. Once downloaded, you will have lifetime single-user access to the CG course material.

When will I receive the course location and the workshop details ?

Registration confirmation email and the courseware access will be shared immediately after the registration. Other details such as location, venue, timing’s. do’s and don’ts will shared 5 day prior for in-person classroom training and link to join the class, timing’s (time zone) details will be shared 24 our prior to the class.

How do I reschedule OR cancel my enrolment ?

Absolutely yes, you need to drop an email to with your request, and depending upon when you raise a refund or rescheduling request, a fee will be applicable. To learn more, please read our refund policy.

What I will learn?

- Lean principles for waste elimination

- Six Sigma DMAIC methodology (Define, Measure, Analyze, Improve, Control)

- Root cause analysis and statistical problem-solving tools

- Process mapping, SIPOC, and value stream mapping

- Hypothesis testing and inferential statistics

- Design of Experiments (DOE)

- Statistical Process Control (SPC)

- Managing improvement projects and organizational change

Course Agenda

Day 1

Introduction

-

Introduction to PMI, PMP, and Course

-

Certification Guide, Instructor, Participant introduction and Set expectation by participant

Module 01 : Overview of Lean and Six Sigma

-

Organizational Objective

-

Introduction, Deliverables, and Benefits of Lean Six Sigma Yellow Belt

-

Introduction, Deliverables, and Benefits of Lean Six Sigma Green Belt

-

Introduction, Deliverables, Benefits of Lean Six Sigma Black Belt

-

Profit

-

Course Overview

Module 02 : Six Sigma: The Basics

-

The Meaning of Six Sigma

-

Problem solving strategy

-

History of Six Sigma and Continuous Improvement

-

Roles and Responsibilities

-

Project Team Selection

Module 03 : Six Sigma: The Fundamentals

-

Voice of Customer

-

Critical to Quality (CTQ)

-

Affinity Diagrams & Pareto Analysis (80:20)

-

Cost of Poor Quality

-

Six Sigma Projects: DMAIC

-

Basic Six Sigma Matrix

Module 04 : Project Management

-

Change

-

Project Management Basics

-

Business Case and Project Charter

-

Cost Benefit Analysis

-

Project Risk Management

-

Failure Mode & Effects Analysis (FMEA)

Day 2

Module 05 : Lean

-

Understanding Lean

-

Lean: History

-

Lean vs 7 Deadly Wastes

-

Lean and Six Sigma

Measure

Module 06 : Process Definition

-

Process Mapping, SIPOC, Value Stream Map

-

XY Matrix

Module 07 : Six Sigma Statistics

-

Basic Statistics

-

Descriptive Statistics

-

Distribution and Normality

-

Graphical Analysis

Module 08 : Measurement System Analysis

-

Precision & Accuracy

-

Accuracy: BIAS, Linearity & Stability

-

Variable MSA: GRR

-

Stability

Module 09 :Process Capability

-

Capability Analysis

-

Attribute and Discrete Capabilities

Day 3 : Analyze

Module 10 : Patterns of Variation

-

MultiVari Analysis

-

Classes of Distributions

Module 11 : Inferential Statistics

-

Understanding Inference

-

Sampling Techniques and Uses

Module 12 : Hypothesis Testing

-

General concepts and goals of Hypothesis testing

-

Significance Practical vs Statistical

-

Risk: Alpha & Beta

-

Hypothesis Testing

-

Reading tables

-

Excel: Data Analysis ToolPak

-

Testing from Normality

Module 13 : Hypothesis Testing with Normal Data

-

Test of Equal Variance

-

Z Tests

-

1 Sample T Test

-

2 Sample T Test

-

Sample Variance: Chi Square

-

One Way Anova

Day 4

Module 14 : Hypothesis Testing with Non-Normal Data

-

MannWhitney

-

Kruskal Wallis

-

Mood’s Median

-

Friedman

-

1 Sample Sign

-

1 Sample Wilcoxon

-

One and two Sample proportion

-

ChiSquared

Improve

Root Cause Analysis

Module 15 : Correlation and Linear regression

-

Correlation

-

Scatter Plot/ XY Diagram

-

Regression Analysis

-

Residuals Analysis

-

Multiple Linear Regressions

-

Data Transformation, Box, Cox

Module 16 : Design of Experiments (DOE)

-

Designed Experiments

-

Full Factorial Experiments

-

Fractional Factorial Experiments

Module 17 : Lean Tools and Practices

-

Lean:5s Visual Factory & Standardized work

-

Lean: Kaizen, Kanban & PokaYoke

Day 5 : Control

Module 18 : Statistical Process Control (SPC)

-

Data Collection for SPC

-

Control Chart Structure and Rules

-

IMR Chart

-

XbarR Chart

-

XbarS Chart

-

NPChart

-

PChart

-

CChart

-

UChart

-

CumSum Chart

-

EWMA Chart

Module 19 : Six Sigma Control Plans

-

Control Plans

-

Module 20 : Lean Controls

Final Exam Session

Student Ratings & Reviews

No Review Yet